State-of-the-Art In-house Lab

Every component sourced on your behalf is carefully inspected in our in-house lab. You can depend on:

- Professionally trained, experienced & certified inspectors

- State of the art temperature & humidity controlled ESD compliant inspection lab

- Thorough in-house component inspections based on IDEA- STD-1010 & J-STD-033 standards

- Detailed general shipping container inspection

- Meticulous package contents inspection

- SMD chip counter to verify exact component counts

- Visual part marking verification to establish conformance to OCM requirements & ensure authenticity

- Mechanical inspection of dimensioned features as sanded, blacktopped parts typically

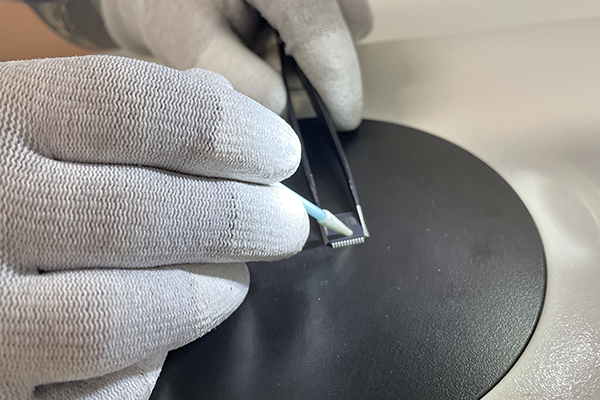

do not meet dimensional specifications - Acetone testing to detect blacktopping or resurfacing

- Remarking & permanency tests to detect older date codes, slow-speed devices, or refurbished components

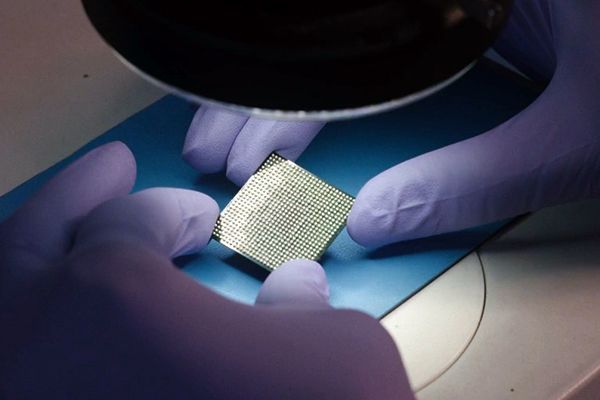

- Further visual inspection using microscopy to detect flaws or inconsistencies on surfaces or leads

Comprehensive Component Testing

Our mission is to source and deliver electronic components you can depend on.

“When you need more comprehensive testing VRG can accommodate any number of more detailed component tests based on your individual needs. We have chosen to work with only the very best. Our preferred test house is the most dependable US-based, fully certified laboratory available. We will handle all of the details for you. Just let us know your specific testing requirements.”

Michael Robertson, VRG Components Quality Assurance Manager

Inspections & Testing Services include but aren’t limited to:

COUNTERFEIT MITIGATION

- Packaging Inspection

- External Visual Inspection

- Scanning Electron Microscope

- X-Ray Inspection

- X-Ray Spectroscopy

- Decap Internal Analysis

- Solderability

- Decap Internal Analysis

REMARKING & RESURFACING ANALYSIS

- Acetone Swab Test

- Heated Chemical Test Using Dynasolve 715/750

- Heated Chemical Testing Using 1-Methyl 2-Pyrrolidinone

- Marking Permanency

ELECTRICAL TESTING

- AC/DC Parameters

- Passive Component Tests

- DDR/DRAM Testing

- Pin Correlation

- Functional Testing

- Programming

- JTAG & Boundary Scan

- Speed Verification

- Upscreening

MECHANICAL TESTING

- Particle Impact Noise Detection (PIND)

- Terminal Strength Testing

- IPC 610 Board Inspection

- IPC 620 Wire & Cable Inspection

ENVIRONMENTAL TESTING

- Burn In/HOTL

- Highly Accelerated Stress Test (HAST)

- Humidity & Bias (THB)

- Thermal Shock

INDUSTRY TESTING STANDARDS

- MIL-STD-202

- MIL-STD-750

- MIL-STD-883

- MIL-PRF-55342

- AS6081

- AS6171

VRG Components strives to provide the highest possible level of product quality to our customers and we stand behind every product we sell. Our goal is to consistently meet and exceed your requirements and expectations.